The project

At the request of Robinson Road Planing, Simtec carried out a mix design for cement bound recycled material (CBRM) to be manufactured from planed material stored at the client’s premises near Ripon. The client also required a classification of the resultant mix to promote the use of the product as a road repair material.

The reuse of planed material has numerous benefits, including negating the need for expensive disposal of hazardous waste and also savings in the use of primary aggregates for road repair.

Two stockpiles of planings, one tar bound, and one bitumen bound, were sampled by one of our fully accredited technicians. Three samples of bitumen-bound planings and three samples of tar-bound planings were obtained in accordance with BS EN 12697 Part 27:2017. All relevant protocols for handling hazardous materials were observed, and the samples, suitably sealed, were returned to our laboratory at East Goscote in Leicestershire for further testing. Samples of the cement and the filler material to be used were also collected during the visit to ensure the trial mix was representative of the product to be made.

The challenge

Washed gradings in accordance with BS EN 933-1:2012 were carried out on all six “as received” planing samples, the filler material, and the cement. Further washed gradings were carried out after filler material was added and again after the addition of filler and cement.

An Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) were determined by carrying out vibrating hammer Reference Density and water content as per BS EN 13286-4:2003.

Briquette samples were produced in accordance with SHW Series 900 Clause 948 and Transport Research Laboratory report TRL 611. These samples were produced and compacted at the OMC, cured, and submitted for indirect tensile stiffness modulus (ITSM) testing.

ITSM tests were carried out on the submitted samples in accordance with BS EN12697-26:2004 Annex C.

The initial samples of planings were found, as expected, to be coarse when compared to the grading curves given in TRL611. The addition of filler was employed to produce a mix compliant with the grading requirements of Zone C.

Previously manufactured CBRM had proved too stiff, so the addition of cement was kept to the minimum permissible in this initial design mix.

The solution

The OMC and MDD values were used to produce a total of nine briquettes for stiffness testing, three of which were tested at 14-day curing to check the strength gain and give an indication of the final likely result.

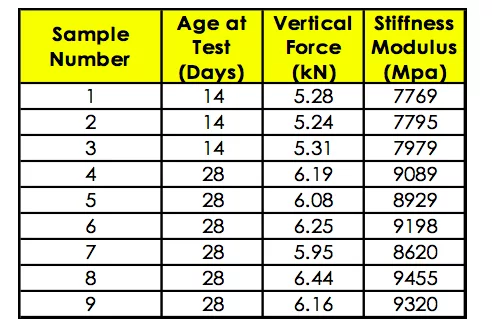

The table below gives the results at both 14 and 28 days.

A consistent stiffness modulus was returned with an average value of 9.102 GPa using the minimum cement content.

A further set of briquette samples was produced in accordance with SHW Series 900 Clause 948 and TRL 611 using the same mix design as the originals. On completion of the curing period, the briquettes were subjected to indirect tensile stiffness testing in accordance with BS EN 13286-42:2003 and the results of this testing are reported in tabular form below.

Mean Value for the set of six samples = 0.483 MPa

To enable recycled materials to be incorporated in a pavement design, it is essential that the structural contribution to the pavement is known. This can be satisfactorily achieved by classifying the recycled mix as a function of the relationship between its Dynamic modulus and its Flexural strength as detailed in TRL Report 611 Clause 724. The equation:

Edyn = 8.4+0.93Es

expresses the Dynamic modulus (Edyn) in terms of tested Static stiffness modulus (Es) whilst the equation:

Rf = 1.33Rit

expresses the flexural strength (Rf) as a function of the tested Indirect tensile strength Rit. For the proposed mix, a Static modulus of 9101.8 MPa and Indirect tensile strength 0.483 MPa were established. Using these figures and Figure 7.2 of TRL611 the classification for the mix in this trial was shown to be Zone H2/H3.

This trial was able to produce evidence that the proposed material mix would meet the requirements of local authority specifications for inclusion in pavement maintenance schemes.